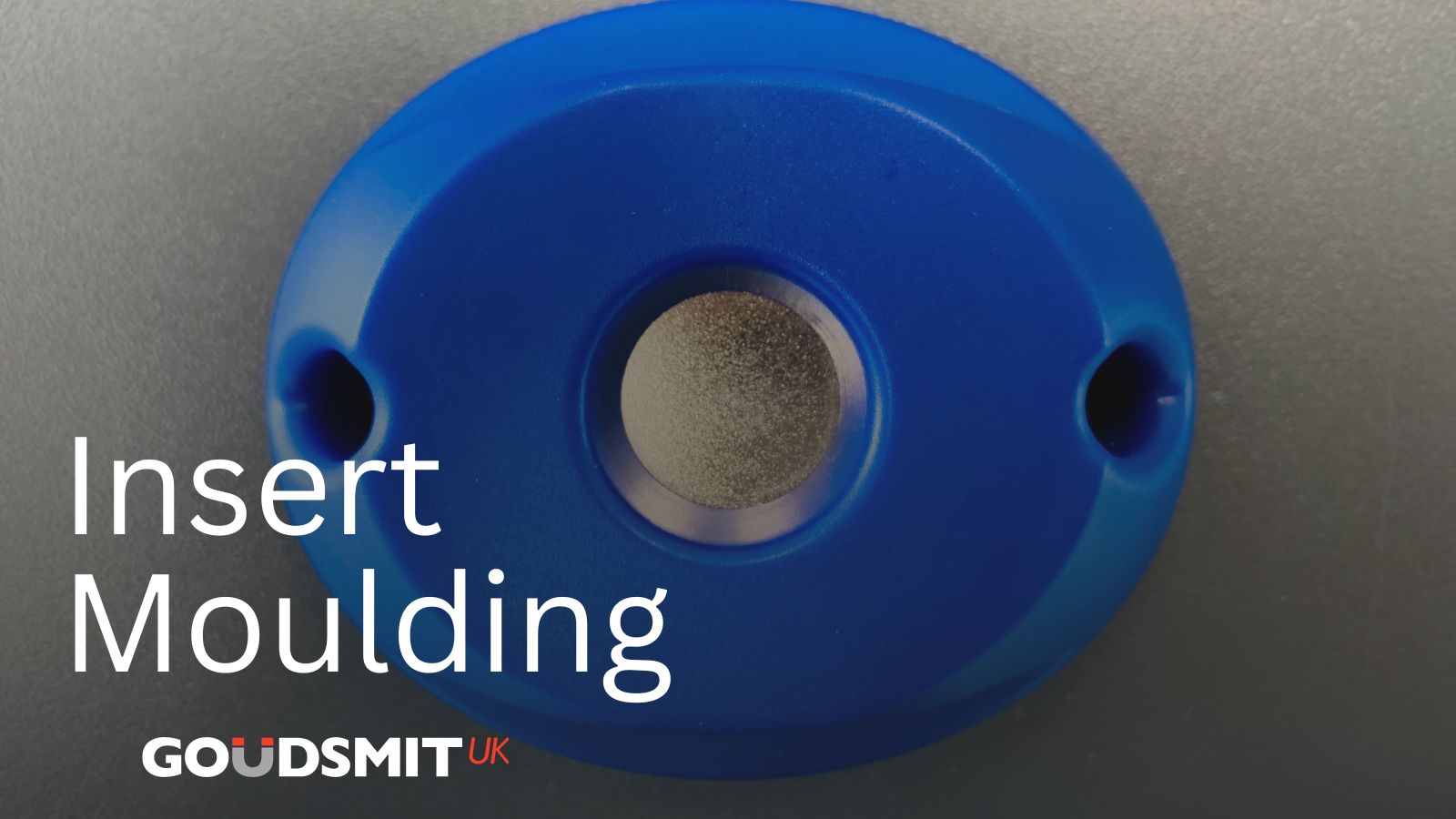

In our last blog post we established that the correct assembly technique is critical for performance. After a detailed look at the pros and cons of mechanical assembly, the insert moulding of magnets is the next assembly technique we’re going to look at.

Insert Moulding

Often described as a manufacturing process that uses advanced injection moulding technology, insert moulding has transformed modern-day manufacturing.

What Is Insert Moulding?

Insert moulding is an assembly technique that enables magnets and plastics to be joined without gluing. This is a very technical solution that requires precision moulds, with a lot of design thought put behind it. The process involves the use of engineered plastics that offer good wear resistance, tensile strength and weight reduction, in addition to some metallic materials that add conductivity and strength. The insert moulding of magnets is a forming technique that uses thermoplastics, thermosetting polymers, and metals that all have a low melting point.

Characteristics

- Insert moulding remains a popular method of magnetic assembly, being widely used throughout the manufacturing industry.

- Insert moulding is best suited to high volume production, enabling multiple moulds to be used.

- It remains the ideal solution for materials with low melting points.

- Products are made faster and cheaper due to quick cycle times and lower costs.

The Process

Insert moulding uses the same materials as the injection moulding process. However, for more extreme, high heat components, engineered thermoplastics are used. Due to the physical, electrical, and chemical properties of these materials, they can withstand very high temperatures. This results in components that can withstand very harsh environments, making them an ideal solution for the renewable energy and the oil & gas industry.

The insert moulding process involves melting plastic, which is supplied as a granulate or powder, to form a fluid mass, then injecting it at high pressure into a mould. The mould contains the magnetic component that is to be inserted, and the remaining cavity is the shape of the final product. As it cools, the plastic solidifies, resulting in the final product prior to any finishing techniques that might be required.

Applications

Known for reducing assembly and labour costs while improving component reliability, insert moulding is the chosen technique for a variety of applications including:

- Aerospace

- Medical

- Automotive

- Consumer Products

Benefits

Insert moulding proves to be advantageous for several reasons:

- Since insert moulding requires thinner products, the cost can be kept low.

- The mould cools off quickly, resulting in a cycle time of just seconds in some cases.

- Stronger, lightweight products are often produced since the insert helps add stability and strength without the need for multiple parts.

- An ability to mass produce the same product during each cycle due to multiple-cavity moulds.

Disadvantages

As with anything, insert moulding has some drawbacks:

- The initial tooling and machinery cost tends to be relatively high.

- There may be restrictions on part design.

Despite these minor challenges, insert moulding is one of the most commonly used forming techniques for plastic parts to produce complex products. However, due to the relatively high cost of making a mould, insert moulding of magnets is only suitable for high volume production.

Goudsmit UK

We have years of experience, and can work closely with you to develop and help manufacture your products. Contact us today for more information at info@goudsmit.co.uk or on +44 (0) 2890 271 001.

For more information download our products and services brochure.