When selecting the right magnet for your project, it’s crucial to have a clear understanding of magnetic materials, their applications, and how environmental factors influence their performance.

This comprehensive guide is designed to assist you in choosing the right magnet for your project.

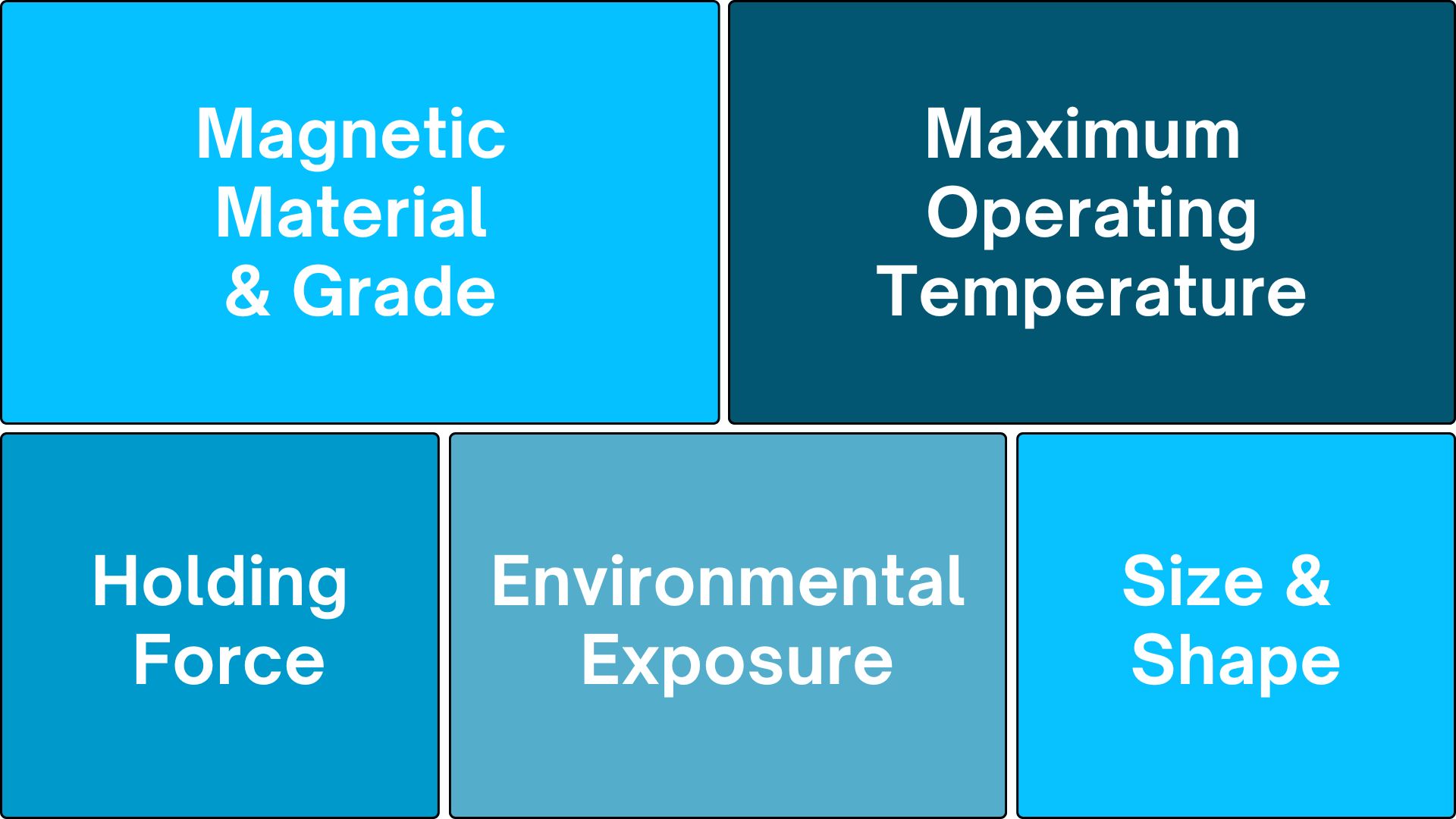

We’ll run through the key considerations that you should take into account when purchasing a magnet – including strength, temperature resistance, application requirements, and shape and size.

We’ll also introduce you to our innovative Goudsmit UK Magnetic Force Calculator, designed to streamline your selection process.

Understanding Magnet Types and Strengths

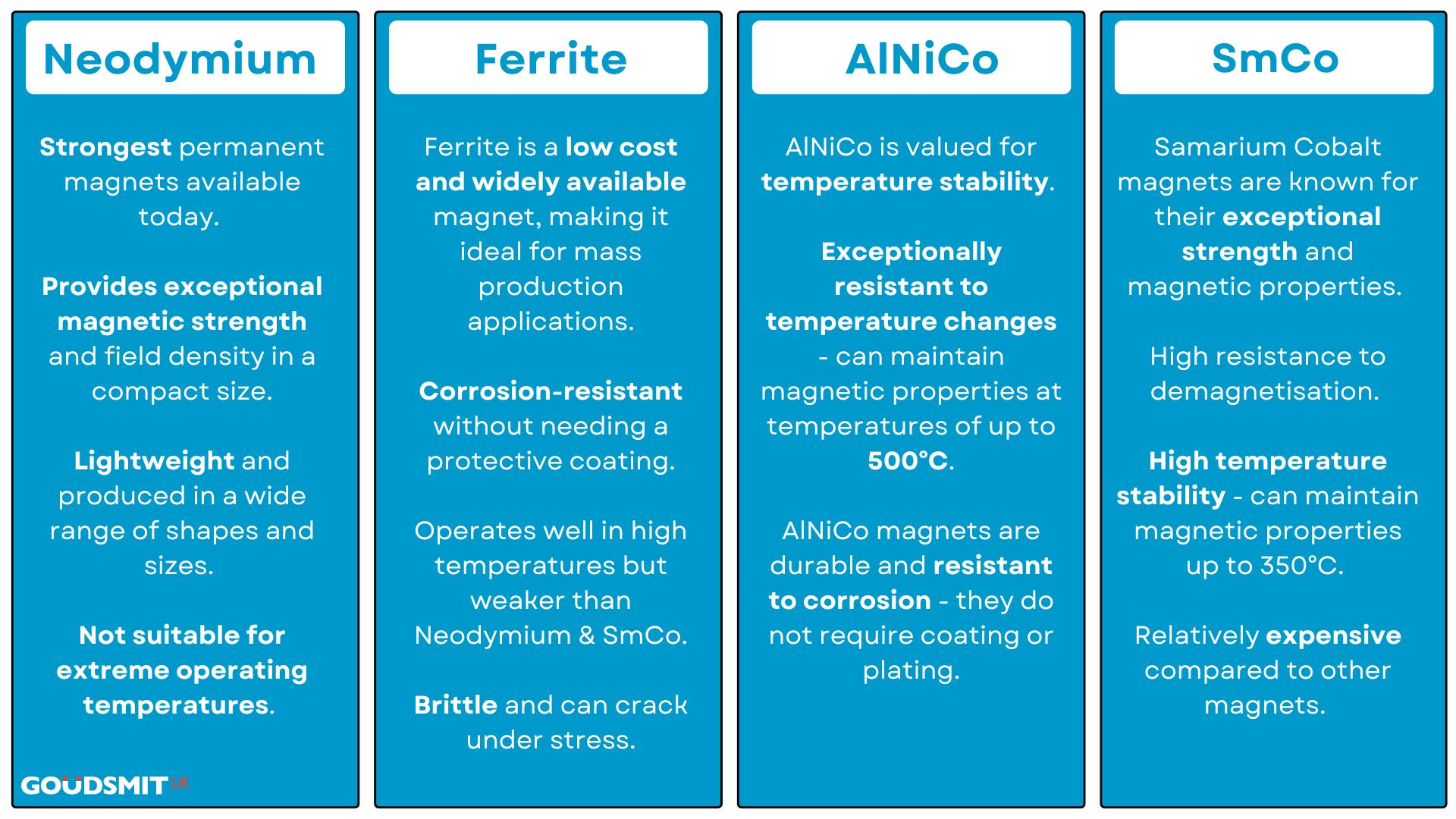

The first step in ensuring you choose the right magnet for your project is understanding the different types of magnets available and their respective strengths. The most common types of magnets are:

Neodymium: Known for their exceptional strength, neodymium magnets are ideal for applications requiring compact size and maximum holding power.

Ferrite: Ferrite magnets are not as strong as Neodymium, but offer a good balance of strength and affordability, making them a cost-effective option suitable for a wide range of applications.

Alnico: Alnico magnets are characterised by their high temperature resistance, and are commonly used in sensors and motors with high operating temperatures.

Samarium Cobalt: Like neodymium, SmCo magnets are part of the rare earth family, offering high magnetic strength, but also excellent temperature stability.

Each type of magnet has its unique set of properties, making it more suitable for certain applications than others.

By considering the specific requirements of your project, such as holding force, size constraints, and exposure to elements, you can narrow down your options effectively. Our team of experts can help guide you in selecting the exact magnet and grade for your application needs.

Magnet Temperature Considerations

Temperature plays a crucial role in magnet selection.

High temperatures can demagnetise certain types of magnets, while others retain their magnetic properties even at elevated temperatures.

| Neodymium | Ferrite | Alnico | Samarium Cobalt | |

|---|---|---|---|---|

| Max Working Temperature: | 230°C | 250°C | 550°C | 350°C |

For instance, some Neodymium magnet grades, despite their high strength, can begin to lose their magnetic properties at temperatures above 80°C (176°F).

In contrast, Samarium Cobalt magnets maintain their magnetism up to 350°C (572°F), making them an excellent choice for high-temperature applications.

When evaluating magnets for your project, consider the environment in which they will operate.

Will they be exposed to high temperatures? Are there fluctuations that could affect performance? Answering these questions will guide you toward a magnet that not only meets your strength requirements but also withstands the operational conditions.

Magnet Application Requirements

Understanding the specific needs of your project is paramount. Consider the following:

Magnetic Holding Force

How much weight does the magnet need to hold? This is a key factor to consider.

Neodymium magnets, for example, are often the best choice when you need maximum strength in a small size. These magnets are also commonly used in high-tech devices, such as smartphones or electric motors, where space is limited but strong magnetic force is essential.

For heavier industrial tasks, like lifting or securing components in the automotive or aerospace industries where performance is critical, neodymium is also the go-to option due to its powerful magnetic properties.

Size and Shape

Space constraints and design specifications often dictate the size and shape of the magnet.

Alnico magnets, for instance, have quite limited size and shape options in comparison to other magnets.

Each magnetic grade has a maximum energy product, which directly contributes to the magnet’s strength. However, it’s important to understand that a magnet’s overall force is also influenced by its size.

If two magnets have identical properties, including the same maximum energy product, the larger magnet will generate more magnetic force.

Whether your project requires thin disc-shaped magnets or more complex configurations, choosing a design that fits seamlessly into your overall system is crucial.

Environmental Exposure

The environment in which the magnet operates can greatly affect its performance.

For example, samarium cobalt magnets are ideal for high-temperature environments such as aerospace or medical equipment, where temperatures can reach extreme levels without causing demagnetization.

Similarly, in marine environments or applications exposed to moisture, chemicals, or corrosion, samarium cobalt provides excellent durability.

On the other hand, ferrite magnets are more suitable for applications where cost is a concern and performance at lower temperatures is acceptable.

They are frequently used in products like loudspeakers or small household appliances, where basic magnetic strength and resistance to environmental changes are required.

The Magnetic Force Calculator: Simplifying Your Selection

To assist you in navigating the complexities of magnet selection, Goudsmit UK offers an innovative tool, our Magnetic Force Calculator.

This user-friendly online tool simplifies the process of determining the correct magnet for your application by considering factors such as material, size and shape.

By inputting your project’s specific needs, the calculator provides instant recommendations, making it easier to find the perfect magnet.

Check out our magnetic force calculator here.

Goudsmit UK

Choosing the right magnet for your project requires careful consideration of various factors, including magnet type, strength, temperature resistance, and also specific application requirements.

By leveraging the insights provided in this guide and utilising Goudsmit UK’s Magnetic Force Calculator, you can make an informed decision that ensures the success of your project.

Moreover, Goudsmit UK is committed to providing high-quality magnetic solutions and unparalleled customer support.

Visit our website to explore our wide range of products and services, and take the first step toward selecting the perfect magnet for your project today.

Remember, the right magnet can make all the difference in the performance and reliability of your application. Choose wisely and let Goudsmit UK be your guide in the world of magnetic solutions.

Download our comprehensive products and services brochure here.