Globally, stricter emission standards have been introduced. Therefore, driving the demand for lightweight vehicles. As a result, demand for aluminium extruded parts in automotive applications has risen and is expected further to rise. As the demand for electric vehicles rises, the market for aluminium extruded parts is expected to grow.

Meeting the challenges for the automotive industry

As the push for reduced emissions and an improved fuel economy continues, aluminium extrusions make an important contribution. Extrusions offer a vast array of solutions to automakers, some examples include:

- Reducing vehicle weight to improve the efficiency of conventional vehicles

- Improving the range of electric vehicles

Increased performance and cost-effective solutions

Using more high strength aluminium, automakers have found a way to ‘slim down’ electric vehicles in order to achieve light weighting. Moreover, automakers continue to use aluminium extrusions in an attempt to make vehicles more energy efficient without sacrificing performance.

In addition to offering expanded capabilities, the extrusion industry also offers modelling and comprehensive testing to maximise performance and efficiency from the initial design stage throughout the entire process.

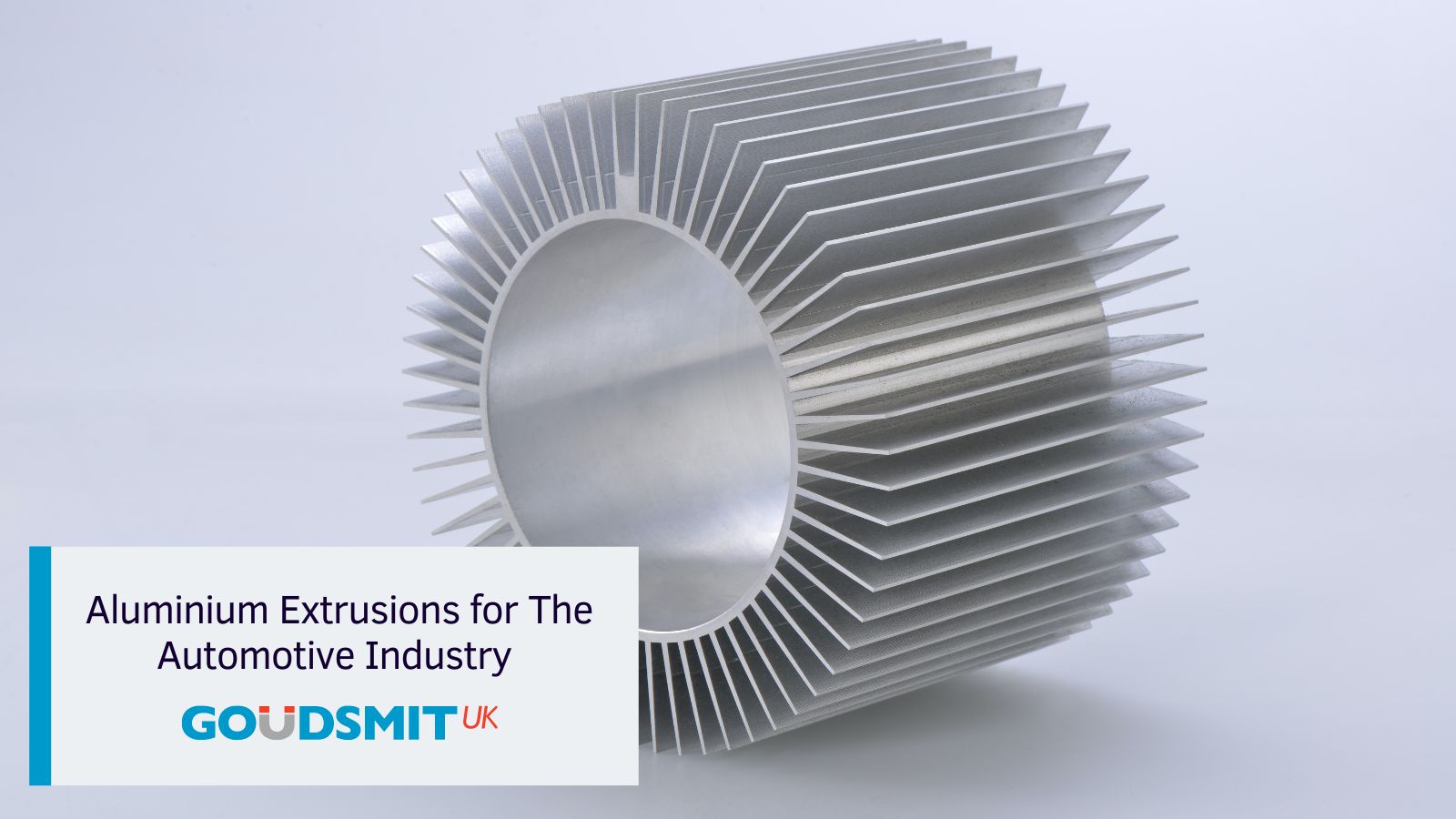

Why aluminium extrusions?

Aluminium extrusions are favoured by automotive designers and engineers worldwide for various reasons. Mainly, utilising aluminium extrusions allows them to use different aluminium alloys to maximise light weighting and also manage the specific application in the vital aspect of energy absorption and crash-management requirements. Further, aluminium extrusions enable automakers to cost effectively meet the 2025 fuel economy and emissions targets when compared to other materials.

Aside from weight savings, aluminium extrusions offer solutions to increase vehicle safety. For this reason, the 6000 series alloys are commonly used as they deliver excellent crash performance, high-yield strength, and reduced weight.

Where are aluminium extrusions used in vehicles?

Generally, the use of aluminium extrusions in vehicles help improve fuel economy, battery range, safety, and overall driving performance. Aluminium extrusions are commonly found in:

- Space frames

- Doors

- Bumpers

- Crash boxes

- Roof headers

- Sub frame

- Battery box

Aluminium extrusions used in vehicles deliver higher-strength and reduced weight. Therefore, resulting in increased energy efficiency, battery power, and energy absorption. All of these factors are essential to differentiate the vehicles and improve their popularity with today’s vehicle buyers.

Goudsmit UK

We produce bespoke extrusions based on your design and volume requirements. Using our advanced capabilities and over 20 years’ experience, we assist you in minimising material content while ensuring that the extruded form (once employed in the application) will work below the maximum yield strength. When combined with our superior quality and complementary services, you are assured that your parts will be production ready.

For more information visit our extrusions webpage or download our brochure.

Contact our team at info@goudsmit.co.uk or on +44 (0) 2890 271 001.